medically compressed gas and dry air system testing|NFPA 99 Medical Air : advice K6042 Breathing Air Gas Contaminant Testing Kit; K6099 Medical Gas Testing Kit; Manufacturing / ISO 8573 Air. K810 P:W:O Testing Kit . Compressed air is often used to dry medical device products and if that air is contaminated with water vapor, the instruments will not completely dry (Chobin, 2017). . A medical device compressed air system .

Odair José. Tentei te esquecer, mas não vejo saída. Não sei tirar você de tudo que eu tenho na minha vida. Eu vejo teu rosto em cada pessoa que passa na rua. Em todos .

{plog:ftitle_list}

Resultado da 12 de nov. de 2017 · Agora estamos postando docs em HD no Dailymotion: Sinopse: O espaço. Ele separa você de mim, uma galáxia de outra, e átomos uns dos outros. Ele está em todos.

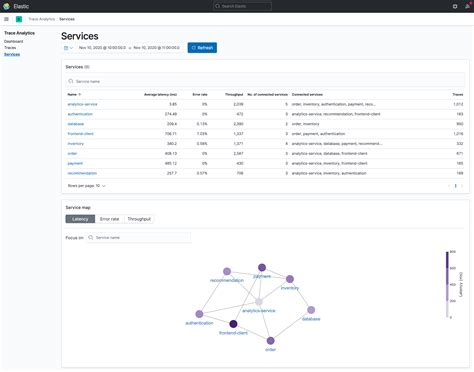

Trace Analytics

For the test conditions for the water content there are also particular characterstics (maximum 67ppm V/V for compressed gas cylinders or max. 870ppm V/V for compressed .A good-size hospital with 200 beds and ten operating rooms can have a medical air system, a laboratory air system, and pneumatic air systems. The medical air systems must all follow the NFPA 99 guidelines.Dry Compressed Air as a Supervisory Gas in Dry Pipe Fire Suppression Systems L. A. Krebs, Ph.D. Anderson Materials Evaluation, Inc. . Water may become trapped in the system during hydrostatic testing, or after a triggering event. Moisture may enter and accumulate in the system through the use of ordinary compressed air as the supervisory gas .

A. Medical oxygen gas system. B. Medical compressed air system. C. Medical vacuum system. D. Nitrous oxide system. E. Nitrogen system. 1.02RELATED REQUIREMENTS A. Section _____: Prefabricated patient bedside units. B. Section _____: Product requirements for bottled medical gases for placement by this section. C. Section 07 8400 - Firestopping.

Requirements for compressed Air in the Pharmaceutical Industry

NFPA 99 Medical Air

Background. In Part 1, I made the case that full system commissioning is needed whenever a compressed air system is significantly modified.And I suggested the following definition of commissioning: .K6042 Breathing Air Gas Contaminant Testing Kit; K6099 Medical Gas Testing Kit; Manufacturing / ISO 8573 Air. K810 P:W:O Testing Kit . Compressed air is often used to dry medical device products and if that air is contaminated with water vapor, the instruments will not completely dry (Chobin, 2017). . A medical device compressed air system . In today’s highly industrialized society, countless processes require the use of compressed air. Industries including Oil & Gas, Petrochemical, Industrial, Environmental, Medical, Food & Beverage, Pharmaceutical, and Airline incorporate compressed air systems in their manufacturing cycles.

Medical gases, commonly known as 'med gas,' are pivotal in modern healthcare, providing vital support in various medical procedures and patient care. These specialized gases, including oxygen, nitrous oxide, medical air, carbon dioxide, helium and various mixtures are integral in multiple applications—from anesthesia and respiratory therapy to sterilization and .

Contact. Nex Flow Air Products Corp. 10520 Yonge Street, Unit 35B Richmond Hill ON., L4C 3C7, Canada. USA / Canada : 1 877-797-2777 International : 1 416- 410-1313 Open a Nex Flow Customer Support TicketTRI Air Testing proudly pioneered the science of compressed air and pure gas testing. TRI’s patented air/gas sampling equipment was designed in 1975 for the U.S. Navy Divers. Since then, TRI Air Testing continues to sponsor the U.S. Navy and Coast Guard D.C.A.T. program as well as other branches of the United States military. Pure gases are used frequently across a range of industries: from food and beverage to hospitals, pharmaceutical, and medical device manufacturing. Depending on the usage of the pure gas, different quality standards and acceptable purity limits may apply. Whether the gas is used for purification, extraction, fermentation, or is administered to patients, it is .

the medical gas pipework systems (MGPS). To avoid confusion they will be referred to as dental compressed air and vacuum systems (DAVS). Medical gas systems should not be used for dental purposes. However, it may be possible to extend a surgical air system into a dental department for dental surgical purposes,Standard Air System Visual Selection Guide 59 Amico Source Medical Air System Selection Table (Oil-Less Scroll Systems) 60-61 Amico Source Medical Air System Selection Table (Oil-Less Reciprocating Systems) 62-63 System Selection Tables Notes 64 5.2.7 Step 7: General Layout 64-66 5.2.8 Step 8: Specification & Schedule 66 Chapter 6 – Medical .

custom meter soil moisture

sources of contamination, the individual contaminants found within a compressed air system and the problems that contaminants can cause: Sources of contamination in a compressed air system . PARTS 2 – 9 SPECIFY THE METHODS OF TESTING FOR A RANGE OF CONTAMINANTS. ISO 8573.1 : 2001 is the primary document used from the ISO 8573 series .

Microbial Testing of Compressed Air Micro Testing of Compressed Air or Bioburden Testing per ISO 8573-7 is generally conducted by the pharmaceutical, medical device and food industries. Microbial contaminants found in the compressor or compressed air lines can be devastating to a final product in these industries. A regular Micro Testing program can provide .In addition to knowledge of product maintenance, a Medical Gas Maintenance worker is required to have a general knowledge of the applicable laws, codes, rules, listing agencies, and regulations from the federal, state, and local levels pertaining to medical gas and vacuum systems as well as knowledge of product performance, system and system . Compressed gases are used at various steps of the pharmaceutical manufacturing process. Applications include weighing stations process line; use of gas to maintain an inert atmosphere above a liquid or . In industry, compressed air is everywhere. Think of it like electricity – a power source that drives conveyers, packaging lines, spray-painting equipment, metal presses – the list goes on and on. But this comes at a cost, .

K6042 Breathing Air Gas Contaminant Testing Kit; K6099 Medical Gas Testing Kit; Manufacturing / ISO 8573 Air . Clean, dry air for pneumatic instruments addresses dewpoint, particle size, lubricant, and contaminants. . add-ons, . We specifically design our products to provide exceptional performance and stand the test of time—a must for every industry. Service. Our goal is perfection, supporting every customer in any area that is needed. . Next Air & Gas Compressed Air Dryers provide industrial-grade dry air and gas to a variety of industries, including automotive .

Table of Contents 1 Potential hazards 2 Storage area basics 3 Storage area conditions 4 Securing cylinders in storage 5 Temperature exposure 6 Storing and returning empty cylinders 7 Handling compressed gas cylinders 8 Conclusion: Safe storage and handling of compressed gases Please note: The information in this guide is general information and should not be used as . While many compressed air applications require a high degree of purity, all compressed air applications work better if the air is clean and dry. However, when the air leaves a compressor, it is anything but clean and dry. Chart taken from ISO8573.1 : 2001 Sources of Contamination Contaminants in compressed air systems have three possible . Compressed air is popularly known as the “fourth utility,” alongside water, gas, and electricity. Several industries rely on compressed air to power their pneumatic tools and machinery, such as air tools and railcar door openers. Important industries using compressed air include manufacturing, automotive, and food processing.

Medical air is a type of compressed air used in the healthcare industry to provide respiratory support and other medical treatments. Medical air systems are designed to provide a safe and sterile environment for medical professionals to perform their duties. It is produced by compressing ambient air and then filtering it to remove impurities, such as dust and moisture.

FOOD AND DRUG ADMINISTRATION COMPLIANCE PROGRAM GUIDANCE MANUAL SUBJECT: COMPRESSEDMEDICAL GASES March Cross-reference: 7356.002(version 02/01/2002)

The quality of air required throughout a typical compressed air system can vary. The extensive range of purification equipment available from Parker domnick hunter allows the user to specify the quality of air for every application, from general purpose ring main protection, through to critical clean dry air (CDA) point of use systems. Parker .generate, and supply oxygen, compressed air, carbon dioxide, nitrous oxide, vacuum and nitrogen to patient care areas. b. Qualified Staff. Qualified staff members are individuals trained in the installation, maintenance, and testing of Medical Gas and Vacuum Systems as required by NFPA 99. c. Qualified Third Party.

A compressed air system is a network of components and equipment that generates, stores, and distributes compressed air. Typically, a compressor directs air to a higher pressure into tanks for storage. From there, a distribution system can release it to power pneumatic devices and machinery.The Dräger compressed air systems use 3 separate compressors, each with 2 redundant pressure tanks, filter systems, compressed air conditioners and pressure reducer stations. This makes maintenance and repairs possible without interruption of the air supply, offering additional operational security.

WEBExclusive No-Love Zone / Beta No-Love Zone / Exclusive Love Restricted Area / Friend zone Only / 专属恋爱禁区 / 恋爱禁止区域 / 배타적 연애 금지구역 / 배타적 연애금지구역 .

medically compressed gas and dry air system testing|NFPA 99 Medical Air